ASTM F1717

Spine Corpectomy Model

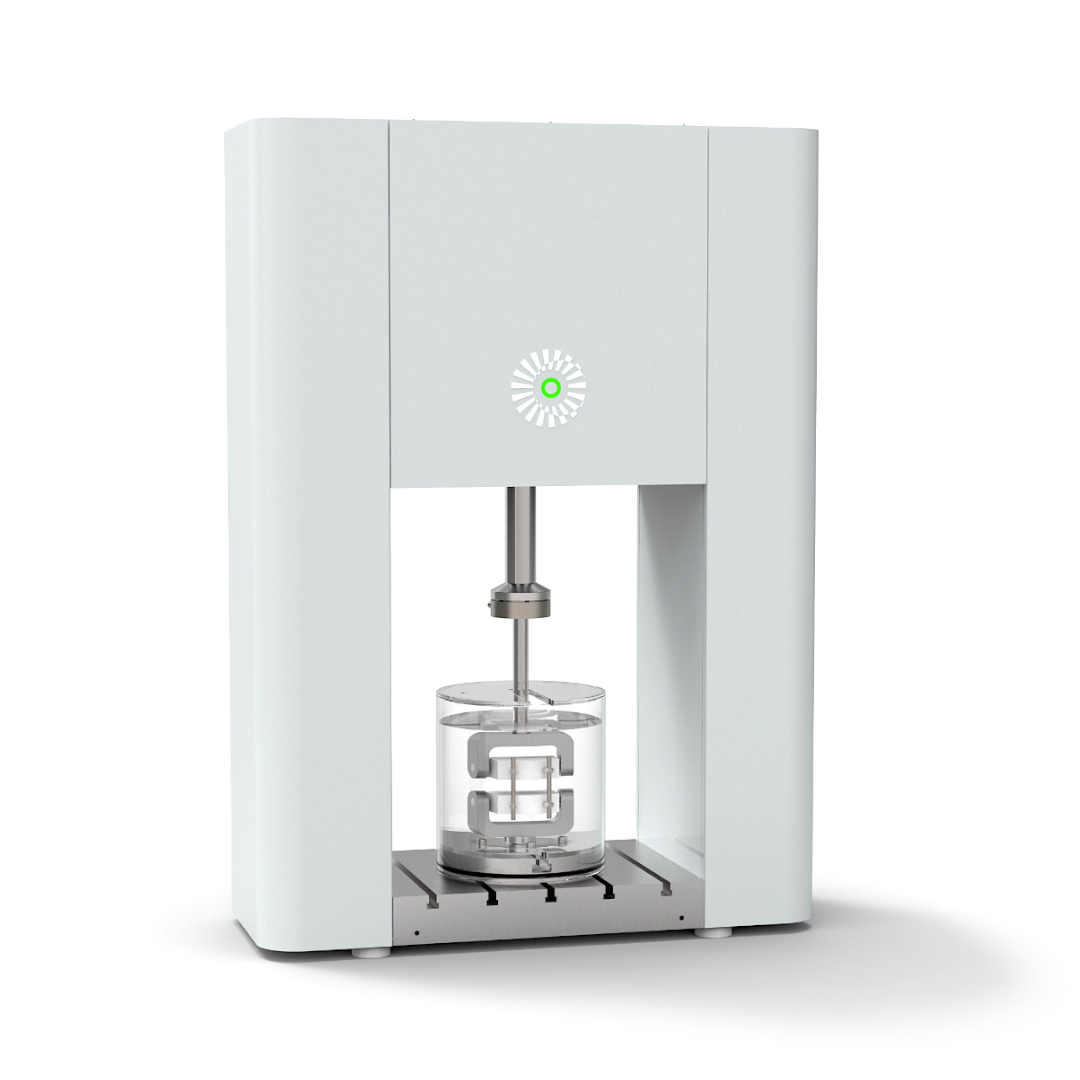

Dynamic testing machines from THELKIN are suitable for testing spinal implants in accordance with ASTM F1717.

Background

The strength of implants for the fixation of vertebral bodies must be investigated for research and development purposes as well as for market approval. This includes the examination of their fatigue properties. Test standard ASTM ASTM F 1717 defines the requirements for an investigation of the fatigue strength of semi-rigid implant constructions. Methodology and applicable parameters as well as the conditions for environmental simulation are described.

Test Setup

The test fixture consists of two parallel arranged bearing bolts, which can be loaded with axial force via u-shaped specimen grips. The spinal implant is fixed in two plastic blocks, which are rotatable mounted on the bearing bolts.

A cyclic, sinusoidal load is applied to the implant until the specimen breaks or until a maximum number of cycles is reached. Test frequencies of 5 Hz are common for this purpose. The test can be performed in air under laboratory conditions or in liquid test medium at 37°C body temperature.

The test result is documented as the number of cycles achieved, together with the applied force amplitude.

Equipment

The fatigue test in accordance with ASTM ASTM F 1717 can be performed easily, reliably and reproducibly with servo-dynamic testing systems from THELKIN and the corresponding specimen holder:

- THELKIN Servo-Dynamic Load Frame SDL-M-010 - complies with the specifications of the standard and enables simple and safe specimen mounting, programming of the test as well as data acquisition and test execution.

- Fluid Bath EN.FB - for physiologically relevant tests, the test can be performed in body environment. For this purpose, the sample is tested in a liquid bath which can be regulated to a temperature of 37°C.

The test system can also be equipped with an uninterruptible power supply and can therefore safely perform long-term tests.